MAZANHO BOIS is your specialist in building fire protection. Fires in the building not only cause human losses, but are also the cause of several material damages, which can impact an economy considerably. To remedy this, legislators have with the support of building specialists developed standards, laws and regulations to avoid or reduce any damage in the event of a fire in the building. In the latter, the doors are an important element because they allow, among other things, access to the various compartments and must therefore resist fire in case of burning while preventing the spread of flames and smoke. Doors with these features are usually flame or fire doors.

Our technology is essentially based on our know-how and the support of our partners, who provide us with superior quality materials, tested and certified in international laboratories. The European standard EN is our source of inspiration.

We equip hotels, commercial offices, administrations, schools or residences with a large influx of traffic of people and users with our isoplane doors.

They can be executed in flame arrestor and fire arresting versions. These isoplane door blocks consist of a solid or tubular core (fig.). The choice of core type depends on the following requirements:

- Duration of fire resistance

- Thermal insulation

- Acoustic specifications

Fire resistance means that the door burns more slowly and thus increases the time it takes for a fire to spread between two rooms (MAZANHO BOIS doors can withstand up to 60 minutes depending on specifications). There are generally three criteria (fig.).

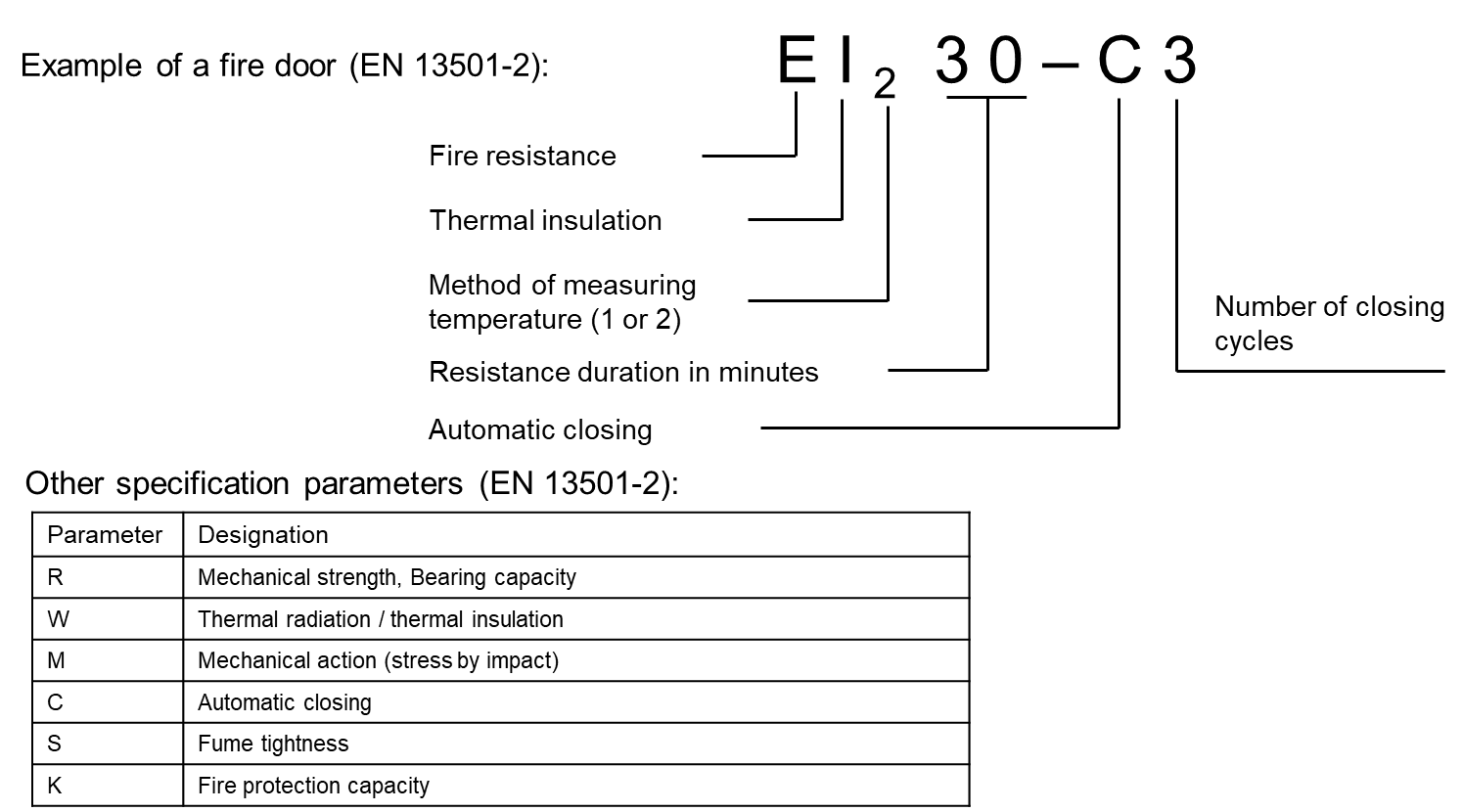

Fire-resistant doors are systematically classified according to EN 13501-2

The duration of fire resistance is defined by the behaviour of the elements subjected to a temperature increase according to a time-temperature curve internationally standardized by ISO 834.

The measurement of thermal intensity is defined by EN 1634-1. There are 2 methods (I1 and I2). The temperature increase of the 5 sensors positioned in a cross in the middle of the leaf must not exceed on average 140 ° C. In addition, a temperature increase of more than 180°C should not be recorded at any point.

Cores

Our insulators, also called cores, are fireproof particleboard, obtained by extrusion processes. They meet several quality criteria such as light weight, impact resistance, no deformation, soundproofing and fire resistance.

We use several types of cores for the realization of our isoplane doors.

The choice of core and its thickness depends on the requirements in terms of fire resistance. We use tubular cores for flame arresting doors, solid cores for fire and slightly isophonic doors and sandwich cores for doors with high isophonic requirements (> 38 dB).

Our tubular core panels have a specific weight of less than 9kg/m2.The specific weight of our solid or sandwich core panels is between 15 and 24 Kg/m2.

Design of isoplane doors

MAZANHO isoplane doors consist of a frame and a leaf. The principle of construction is that of the door with straight or flush edge. This is the most favorable technical form for fire doors, unlike overlay doors that require high leaf thicknesses because of the great depth of the foliage.

The leaf of MAZANHO isoplane doors consists of 3 main elements:

- A hardwood and dry frame (SW)

- A soul (tubular or full)

- Plywood (HDF)

The solid wood frame is generally of IROKO, but any other tropical species of the customer's choice can be used. Its assembly is made by gluing with a suitable glue.

The choice of core and its thickness depends on fire resistance and the degree of acoustic reduction.

The thicknesses of the plywood used vary from 3 to 6 mm depending on the requirements. We offer HDF (High Density Fiber Board) plywood with a density greater than 800 kg/m. This plywood makes it possible to gather the elements of the frame of the leaf as well as the soul on their 2 sides.

We generally use tubular cores for our standard isoplane or flame arrestor doors.

For fire doors our technology is based on the use of solid cores. In addition an isophonic seal and an intumescent seal are integrated into the jambs and crossbeam of the door frame. The isophonic seal prevents the door from slamming. The intumescent seal is a material capable of thickening under the effect of an increase in heat during a fire. They expand with heat, blocking and stopping any air circulation between the leaf and the door frame.

isoplane Acoustic doors

Noise insulation between rooms in a building can be of great necessity (hospitals, offices, etc.). For this type of application, MAZANHO BOIS offers acoustic doors. The concept of our acoustic doors is similar to that of our fireproof isoplane doors.

We use full or sandwiched cores. Their thickness depends on the degree of sound insulation to be obtained. Our acoustic isoplane doors allow a noise attenuation of 28 to 35 dB on doors with a leaf thickness of less than 50 mm. The thickness of the leaf can be increased by increasing the thickness of the core or plywood. In the latter case we use MDF and HDF plywood with different thicknesses. Instead of MDF we can also use cork plates for acoustic reductions of more than 50 dB.